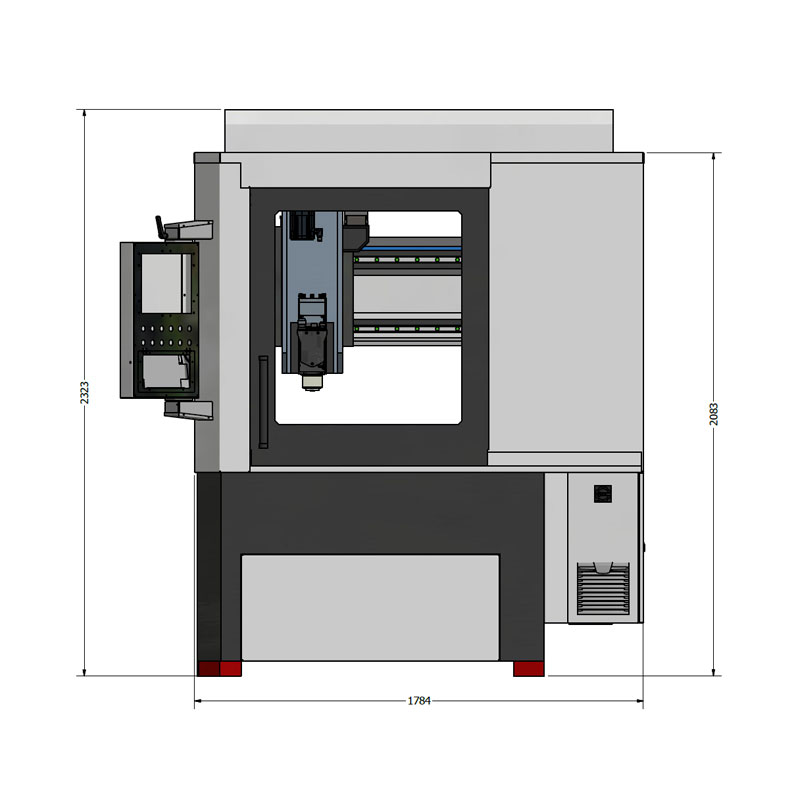

Due to minimum thermal expansion, the form stability, rigidity and the damping characteristics Granite is wonderful for a machine basement. As our machine design has a fixed portal these benefits can be used on all three Axis X, Y, and Z. But still the moving masses are kept small as only machine table and Z-Axis have to move.

The well tuned axis drivers and motors together with state of the art CNC controllers enable high speed and acceleration. Therefore cutting parameters can be kept even in difficult situations and results in outstanding contour accuracy with high feed rate, short processing time and excellent surface quality.

Our CNC special machines

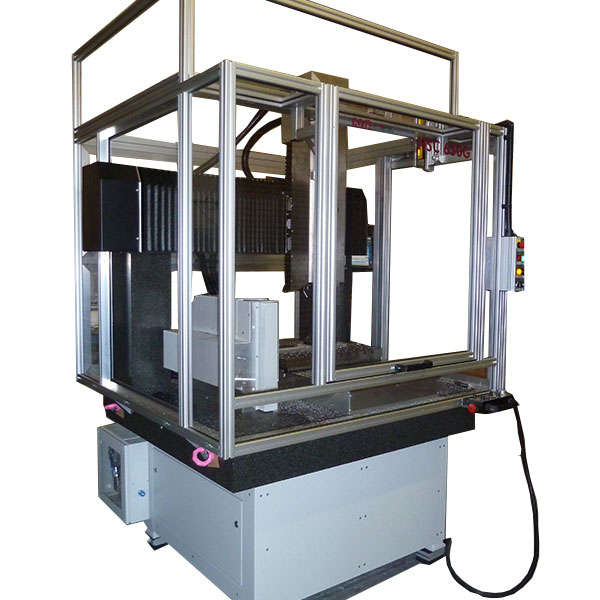

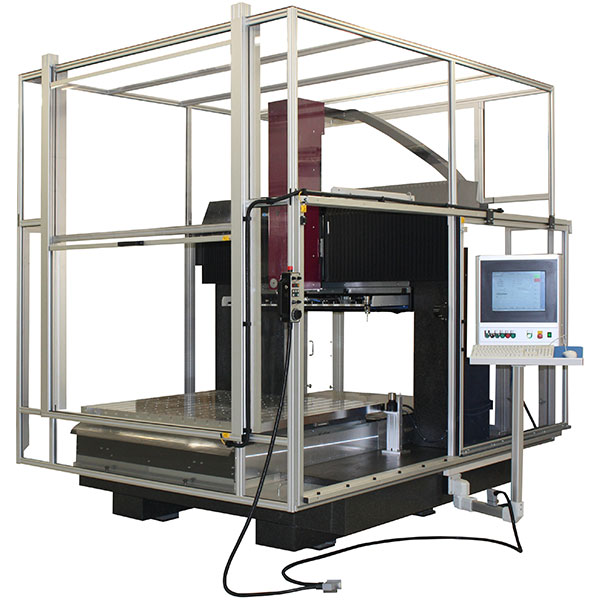

| CNC special machines | HSC 650 G | HSC 1100 G | HSC 1513 G |

|---|---|---|---|

| Travel (XYZ) | 500 mm x 600 mm x 300 mm | 1100 mm x 1100 mm x 400 mm | 1500 mm x 1300 mm x 520 mm |

| Axis of rotation | optional | optional | optional |

| Swivel axis | optional | optional | optional |

| Mounting surface (XY) | 500 mm x 600 mm | 1100 mm x 1100 mm | 1500 mm x 1300 mm |

| max. table load | 250 kg | 500 kg | 500 kg |

| Diffuser height Z | 490 mm | 340 mm | 560 mm |

| max. speed | 12 m/min | 15 m/min | 20 m/min |

| Spindle and tools | |||

| Speed range rpm | 5.000 – 40.000 | 3.000 – 32.000 | 3.000 – 32.000 |

| Spindle power (water cooled) | 4kW (S1-100%), 6kW (S6-40%) | 6kW (S1-100%), 9kW (S6-40%) | 6kW (S1-100%), 9kW (S6-40%) |

| Tool clamping | HSK-E25 | HSK-E40 | HSK-E40 |

| Tool changer | 20x | 18x | 22x |

| max. length from lower edge of spindle cone | 110 mm | 220 mm | 220 mm |

| max. tool length (depending on collet length) approx. | 70 mm | 150 mm | 150 mm |

| Dimensions (XYZ) | 1580 mm x 1660 mm x 2550 mm | 2770 mm x 2130 mm x 2970 mm | 3300 mm x 2660 mm x 3050 mm |

| Table load | 2700 kg | 8000 kg | 10000 kg |

| Compressed air connection | 6 – 7 bar | 6 – 7 bar | 6 – 7 bar |

| Connected load | 3x 400 V / 16 A | 3x 400 V / 16 A | 3x 400 V / 32 A |

| Power | 10 kVA | 10 kVA | 20 kVA |