CAD/CAM & Equipment

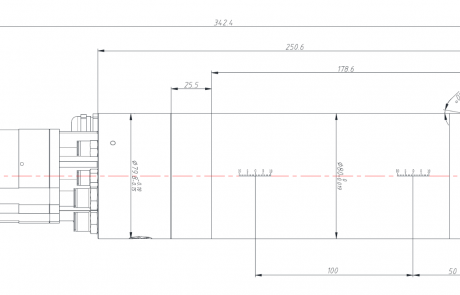

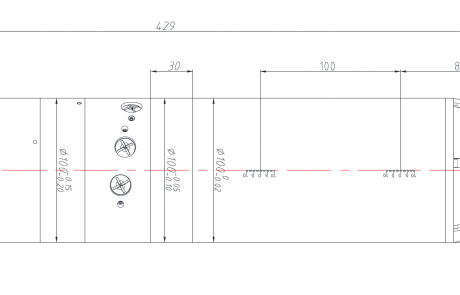

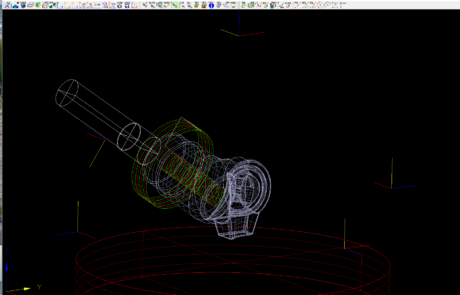

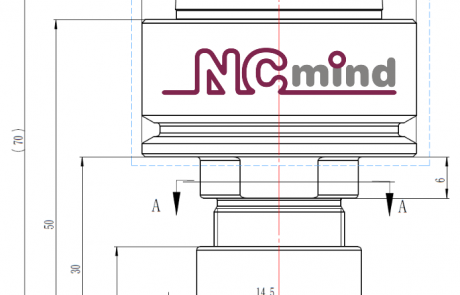

Milling spindles

Specially designed for our HSC milling machines but also perfect for many other use cases – our HSC spindle with standardized diameter and compact outline are universal in use.

Watercooled, powerful and with HSK-E25 or HSK-E40 perfect for automatic tool change.

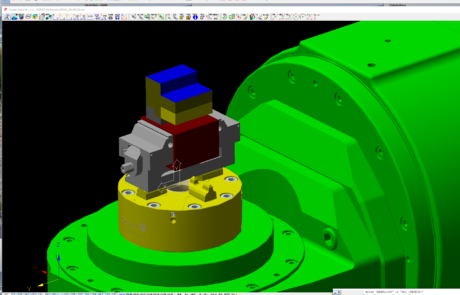

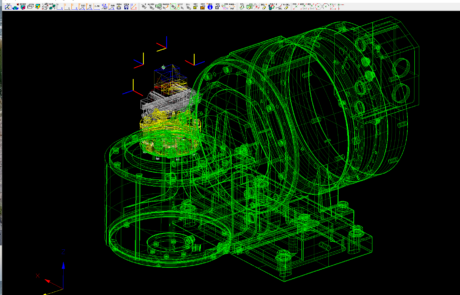

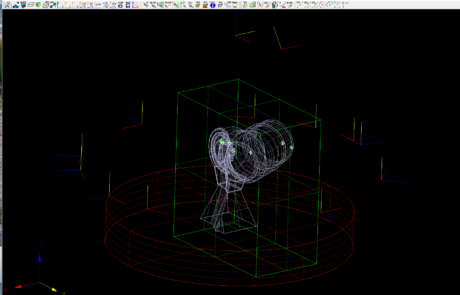

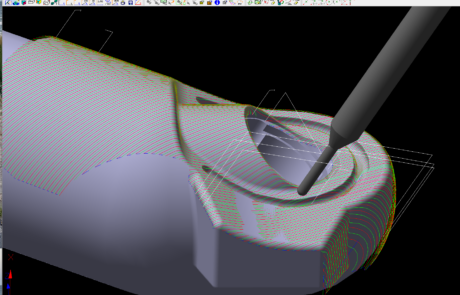

Pictures by PC CAD/CAM

We are Distributer AND User – always ready for your questions!

Pictures by PC from Schott Systeme GmbH is one of the most universal CAD/CAM Systems and the best support for HSC milling. While HSC milling (High Speed Cutting) the material is removed quickly with high feed rate, high tool speed and round trajectories but small immersion into the raw block. Therefore different rough milling and finishing strategies, like contour oriented, spiral or hybrid are available. The later helps to reduce programming time as steep and flat areas are covered with one single work step. Pictures by PC enables you for 3-axis, 5-axis multi view (3+2 axis) and 5 axis simultaneous milling. Due to the post processor fitting perfectly to our machine types the whole CAD/CAM prozess is seemless – even from the very beginnign!

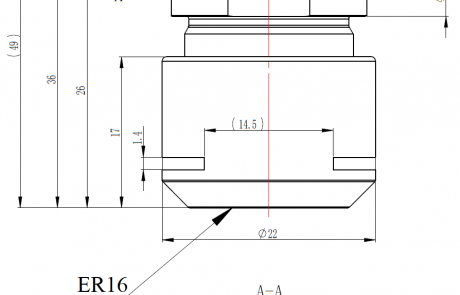

Tool holders and collets

Size Matters – Produce bigger parts or use longer tools on your machine. We deliver the shortest tool holders (collet holders) available.

Furthermore we offer precision grade ER 16 collets – radial runout of the assembly of tool holder and collet <4µm, usually <2µm, for perfect surface and longer tool life.

Additionally we have universal tool holder clamps for HSK-E25 and HSK-E40.

4th – 5th axis – rotational and turn-tilt table devices

rotational devices as turn or tilt-turn table with direct drive torque motors for perfect positioning accuracy. The specialized motors perform with high torque on low and medium speed. The perfect extension for every milling machine.

Many options and accessories available!

We also deliver motor drivers and integration service – ask your questions now.

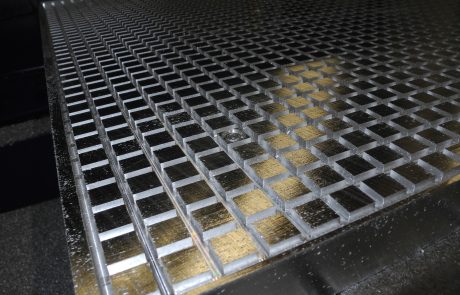

Vacuum tables

We produce various vacuum tables and plates for our machines and for you. Send us your drawing or requirements. Due to inhouse production we can make almost every wish come true like cut outs for rotational device or clamping systems . The system with grid and sealing pipe fits universal to all part dimensions and geometries. Due to fitting holes with steel inserts repeatability is easy and precise.