Fields of application

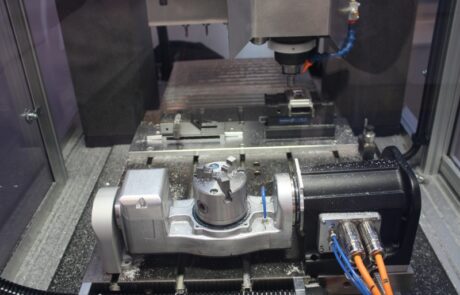

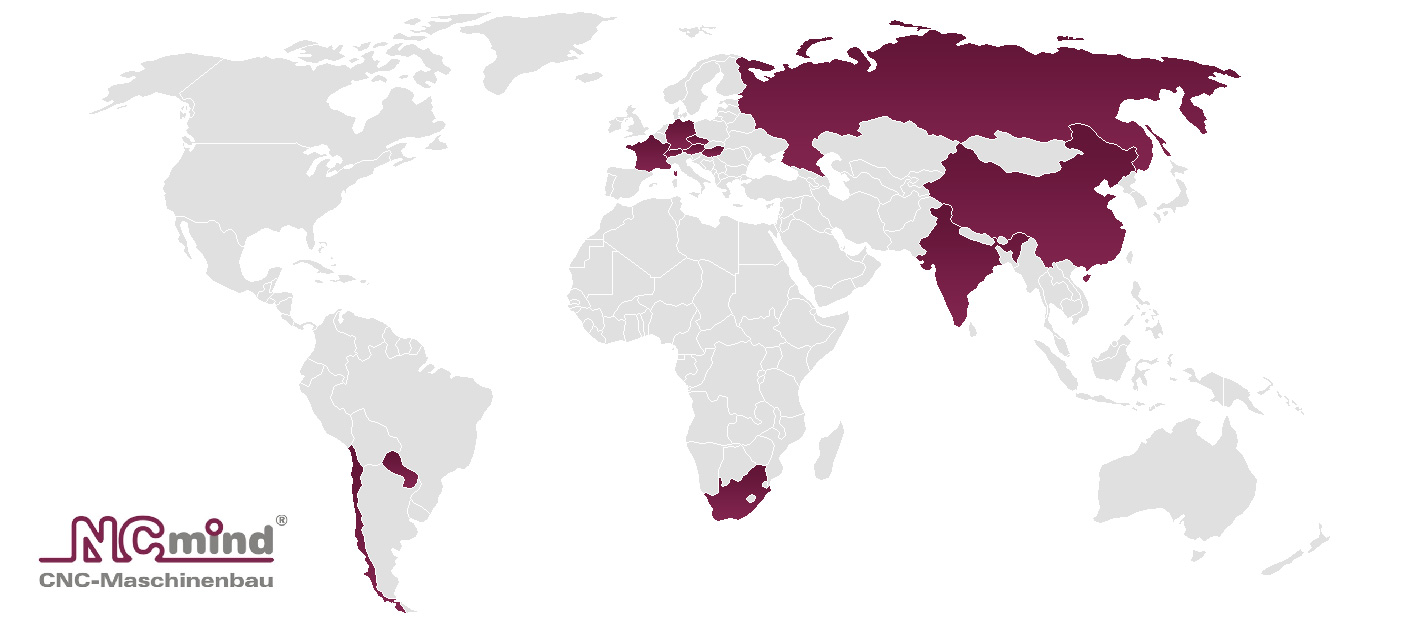

Globally distributed – our CNC machines are in use worldwide

Our CNC machines are in use all over the world. The following map gives you an introductory insight into our geographical areas of application around the world.

The countries shown are Germany, France, Switzerland, Austria, Luxembourg, Hungary, the Czech Republic, Russia, India, Chile and Paraquay.

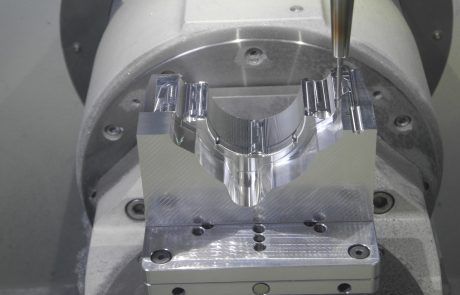

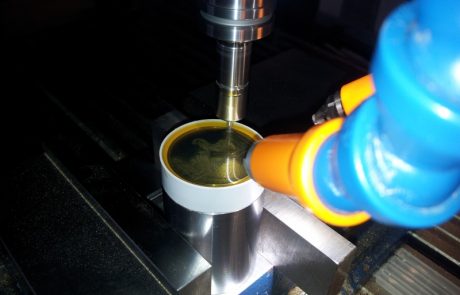

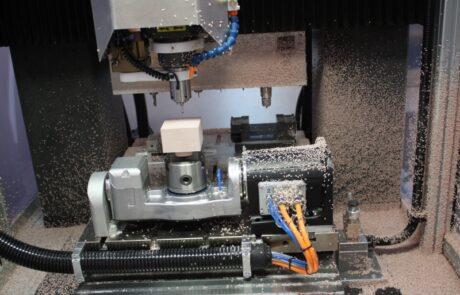

Tool and mold making

The manufacture of tools or tool components using our machines is carried out with the utmost precision.

Our domestic and foreign customers manufacture

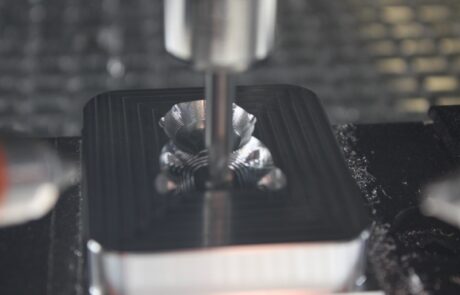

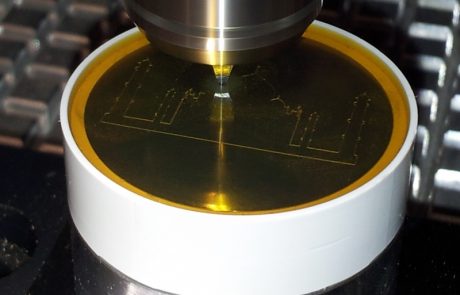

- Electrodes, e.g. made of graphite for erosion applications

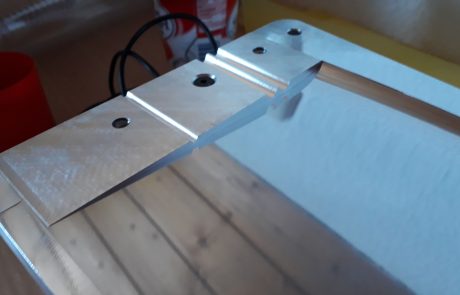

- punching tools

- Injection molding tools

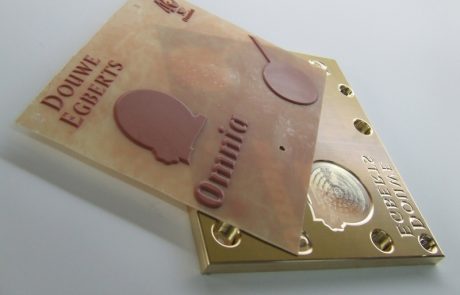

- Molds and embossing tools for the production of security papers in the banking sector or for official documents

- Molds and master models made of aluminum or special plastics for the production of fiber composite plastic parts made of carbon and glass fiber

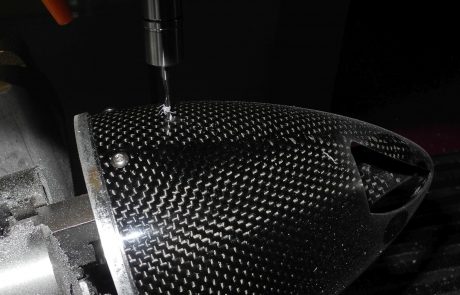

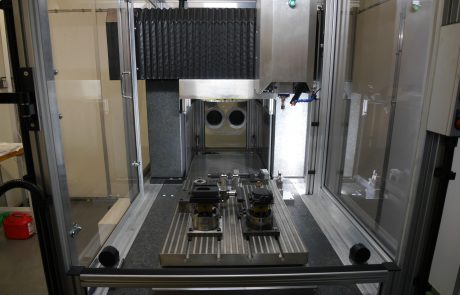

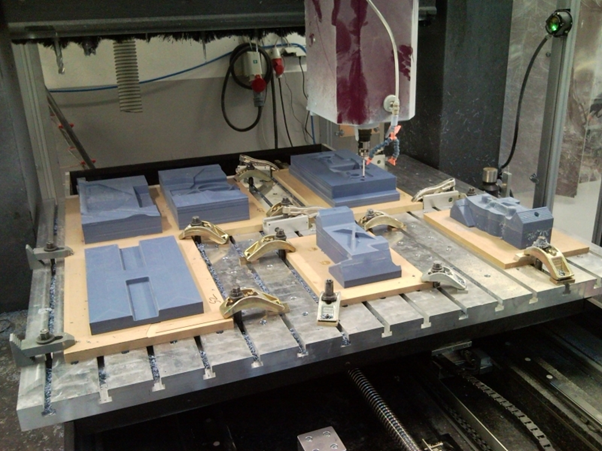

(Re)processing of fiber composite materials, also with dust extraction

Fiber composite and graphite processing with dust extraction

Besides manufacturing models and moulds, working with composite materials suits perfectly with our HSC machines. In the same matter, working with graphite, i.e. for electrodes on eroding tools, has some specialties that are covered excellent with HSC milling. One is the usage of smallest tools down to 0.1mm size and the therefore required high speed spindles and machine precision. Another is the dust extraction. Combined with our machine concept with fixed portal we develop a solution for dust extraction that can live without brushes and nozzles. The big benefit is no parts limit your workspace or bring a risk of damage to your workpiece.

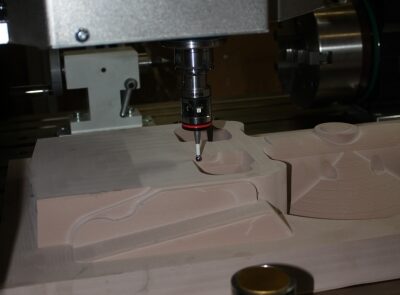

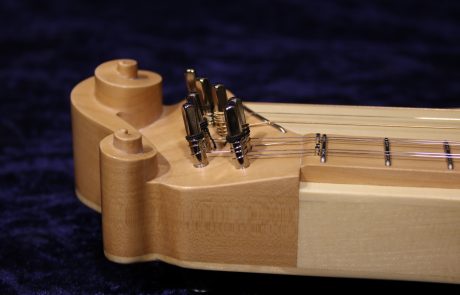

Model making

Using CAD/CAM data, our milling machines create

- functional models,

- prototypes,

- design models or

- negative molds for the production of cast parts.

True to scale is important for the quality of a model.

Precision in the production of the model is a prerequisite for the quality of the planned product.

Rapid-Tooling

Rapid tooling involves the production of tools, in particular plastic injection molds, with reduced cycle times and improved component quality.

Our users are experts in the production of plastic prototypes from original materials. Using 3D data and/or drawings of the component, prototypes are produced whose quality can hardly be distinguished from series products.

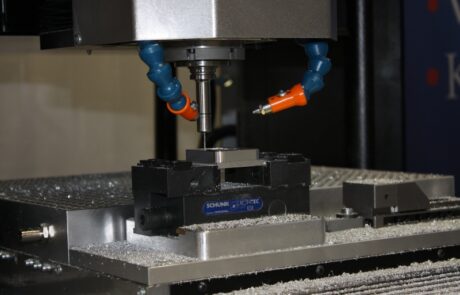

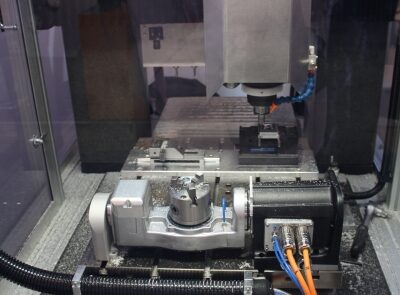

Small series and prototypes

With our HMI user Software you can realize up to 100 individual zero points as well as a flexible Joblist and order processing via network access. Therefore you do not only produce for (small) series but also many different single parts all at once – during the night or over the weekend. Thanks to E-Mail or SMS Messages in case of an error you still sleep well while knowing everything is alright with your production. What you use our machine for, may it be moulds, electrodes, prototypes, dies, embossing tools or cylinders or hundreds of series parts, … and if those are made from Aluminium, (non-ferrous) metals, plastics, graphite, glass or carbon fiber reinforced plastics, … is your decision.

With prototypes as well as with series production – all our tools are a good support. Catching the zero of the raw block or the part to rework with the 3D probe, Programming of the fine milling code while rough milling is already started or the use of special tools that can easily be integrated to the automatic tool changer and tool list or inserted manually – our goal is to make your workflow smooth.

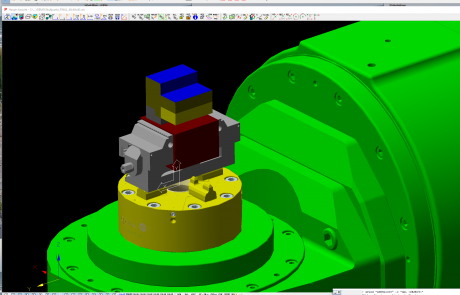

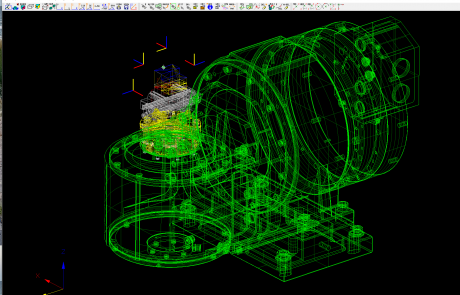

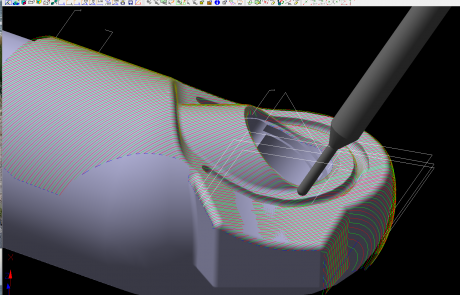

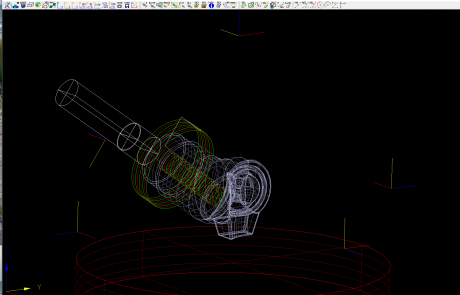

CAD / CAM processing

The generation of machine code with a modern CAM system i.e. “Pictures by PC” from Schott Systeme GmbH (->link zu Zubehör, Pictures) offers a lot of possibilities. Starting with the optimized processing of freeform surface, automatic code generation and 100% machine run time usage due to online code transmission. With our flexible HMI with network connection and joblist all preparations for the next job can be done while machine working – for more efficiency and seamless processes

Engraving applications

Any engraving work can easily be carried out on our CNC machines. Our engraving applications include:

Digitization

Our workpiece probes (measuring or indexing) can be used to determine surface tolerances, transfer them online to the CNC and run milling programs equidistant to the determined surface.

Packaging industry

With our machines, you can produce a wide range of tools for the manufacture of packaging.