HSC 5A-250 MG

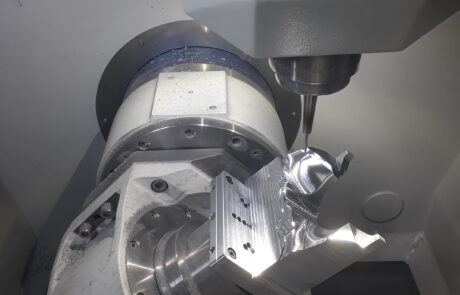

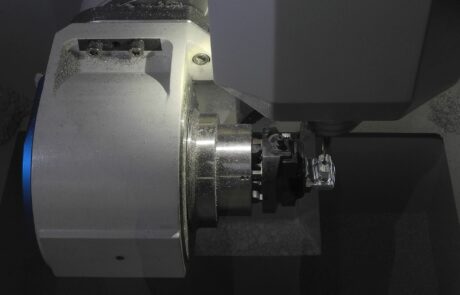

Our big 5 axis machine is neither an extended nor a reworked machine. It is designed for 5 axis milling from the very beginning and made from mineral die cast with all the advantages. Therefore you can mill a 250mm cube (max. part diameter 270mm) from all sides and all directions, without remounting! And even much bigger parts are possible when you do not need all working directions the same time. The linear motors with their direct position measurement system deliver the same outstanding performance as the torque motors do for turn and tilt axis.

Unbelievable 60 station HSK-E25 tool changer helps you out with standard or special tools in single piece production as well as spare tool in series production.

Additionally we offer an automatic handling system for raw material blocks and work pieces. With 32 stations it is prepared for series production.

Standard equipment:

- EROWA zero point clamping system

- Hand wheel for controlling up to 6 axis with override for feed rate and spindle rpm

- automatic tool length measurement and break detection

- joblist and zero point offset management

- network ready machine control for easy access and integration

- semi automatic central lubrication system

Technical data

| Feature | HSC 5A-250 MG |

|---|---|

| Axis count | 5 |

| Travel (XYZ) | 520 mm x 265 mm x 340 mm |

| Axis of rotation | endlos |

| Swivel axis | bis 110° |

| Mounting surface (XY) | X: 250 mm x 250 mm Y: ø 280 mm |

| max. table load | 20 kg |

| Diffuser height Z | 250 mm |

| max. speed | 10 m/min |

| Spindle and tools | |

| Speed range rpm | 5.000 – 40.000 |

| Spindle power (water cooled) | 4kW (S1-100%), 6kW (S6-40%) |

| Tool clamping | HSK-E25 |

| Tool changer | 60x |

| max. length from lower edge of spindle cone | 180 mm |

| max. tool length (depending on collet length) approx. | 140 mm |

| Dimensions (XYZ) | 1610 mm x 1410 mm x 2170 mm |

| Table load | 3300 kg |

| Compressed air connection | 6-7 bar |

| Connected load | 3×400 V / 32 A |

| Power | 15 kVA |