HSC 5A-125 MG

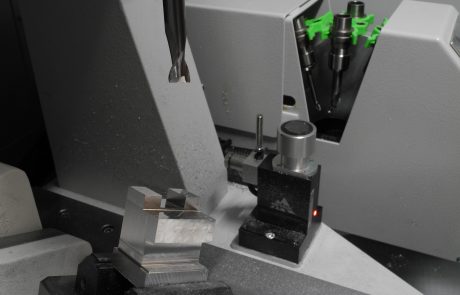

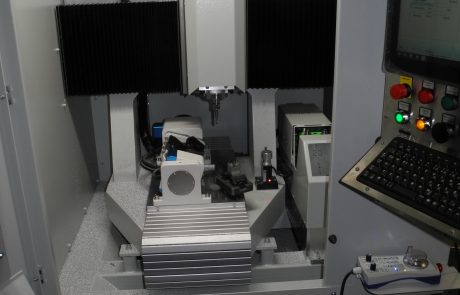

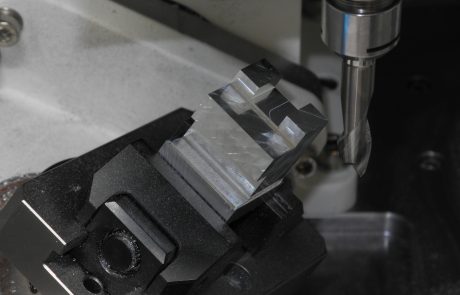

The “little economic miracle” is now also available as 5 axis machine. On the same mineral diecast basement as our HSC 350 MG the HSC 5A-125 MG was born. Therefore you can mill a 125mm cube (max. part diameter 150mm) from all sides and all directions, without remounting! And even much bigger parts are possible when you do not need all working directions the same time.

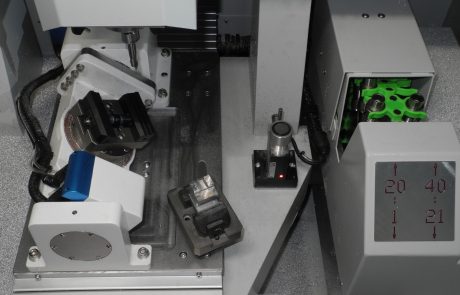

With only 900kg still easy to handle but solid and strong enough for superior cutting volume and outstanding surface quality. The 40-station HSK-E25 tool changer belongs to standard equipment as well as a water cooled 40.000rpm spindle with up to 6kW power.

Our HSC 5A-125 MG is also extremely space efficient! With only 1060mm x 960mm x 2100mm (LxWxH, without operators panel) it fits through almost every door

Technical data

| Feature | HSC 5A-125 MG |

|---|---|

| Axis count | 5 |

| Travel (XYZ) |

380 mm x 180 mm x 220 mm |

| Axis of rotation | endlos |

| Swivel axis | bis 110° |

| Mounting surface (XY) |

X: 125 mm x 125 mm Y: ø 150 mm |

| max. table load | 15 kg |

| Durchlasshöhe Z | 125 mm |

| max. speed | 7 m/min |

| Spindle and tools | |

| Speed range rpm | 5.000 – 40.000 |

| Spindle power (water cooled) | 4kW (S1-100%), 6kW (S6-40%) |

| Tool clamping | HSK-E25 |

| Tool changer | 40x |

| max. Länge ab Unterkante | 110 mm |

| max. length from lower edge of spindle cone | 70 mm |

| Dimensions (XYZ) |

1070 mm x 1010 mm x 2170 mm |

| Gewicht | 900 kg |

| Compressed air connection | 6-7 bar |

| Connected load | 3×400 V / 16 A |

| Power | 10 kVA |