CNC machines

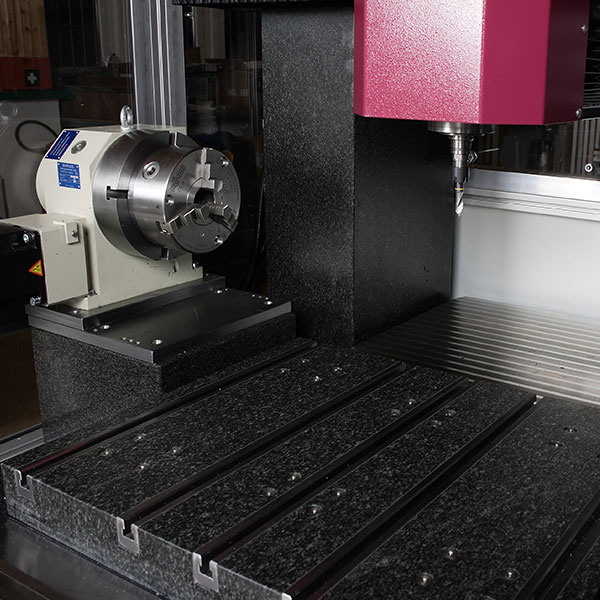

Our milling machines based on mineral die cast are compact, durable, rigid and easy to maintain. Last but not least, due to the high mass they produce excellent surface quality. 20 years of engineering experience and requirements of more than 100 customers worldwide are included in the practical design.

Besides the concept of having a machine with a fixed portal, that reduces moving masses to the minimum possible, the well tuned axis drivers and motors together with state of the art CNC controllers enable high speed and acceleration. Therefore cutting parameters can be kept even in difficult situations and results in outstanding contour accuracy with high feed rate, short processing time and excellent surface quality.

We call them the “economic miracle”! Due to the high level of vertical integration and the short delivery routes we are able to deliver a series of machines with unbelievable price performance ratio – Made in Germany!

An overview of our CNC machines

| Feature | HSC 350 MG | HSC 540 MG | HSC 750 MG | HSC 5A-125 MG | HSC 5A-250 MG |

|---|---|---|---|---|---|

| Axis count | 3 | 3 | 3 | 5 | 5 |

| Travel (XYZ) |

380 mm x 350 mm x 180 mm |

550 mm x 450 mm x 260 mm |

780 mm x 550 mm x 400 mm |

380 mm x 220 mm x 220 mm |

520 mm x 265 mm x 340 mm |

| Axis of rotation | optional | optional | optional | endlos | endlos |

| Swivel axis | optional | optional | optional | bis 110° | bis 110° |

| Mounting surface (XY) |

368 mm x 360 mm |

540 mm x 440 mm |

750 mm x 500 mm |

125 mm x 125 mm ø 150 mm |

250 mm x 250 mm ø 280 mm |

| max. table load | 150 kg | 250 kg | 350 kg | 15 kg | 30 kg |

| Diffuser height Z | 210 mm | 290 mm | 450 mm | 125 mm | 250 mm |

| max. speed | 7 (10)* m/min | 12 m/min | 15 m/min | 7 m/min | 10 m/min |

| Spindle and tools |

|||||

| Speed range rpm | 5.000 – 40.000 | 3.000 – 32.000 | 3.000 – 32.000 | 5.000 – 40.000 | 5.000 – 40.000 |

| Spindle power (water cooled) | 4kW (S1-100%), 6kW (S6-40%) | 6kW (S1-100%), 9kW (S6-40%) | 6kW (S1-100%), 9kW (S6-40%) | 4kW (S1-100%), 6kW (S6-40%) | 4kW (S1-100%), 6kW (S6-40%) |

| Tool clamping | HSK-E25 | HSK-E40 | HSK-E40 | HSK-E25 | HSK-E25 |

| Tool changer | 40x | 24x | 40x | 40x | 60x |

| max. length from lower edge of spindle cone | 110 mm | 200 mm | 180 mm | 110 mm | 180 mm |

| max. tool length (depending on collet length) approx. | 70 mm | 130 mm | 110 mm | 70 mm | 140 mm |

| Mounting surface (XYZ) |

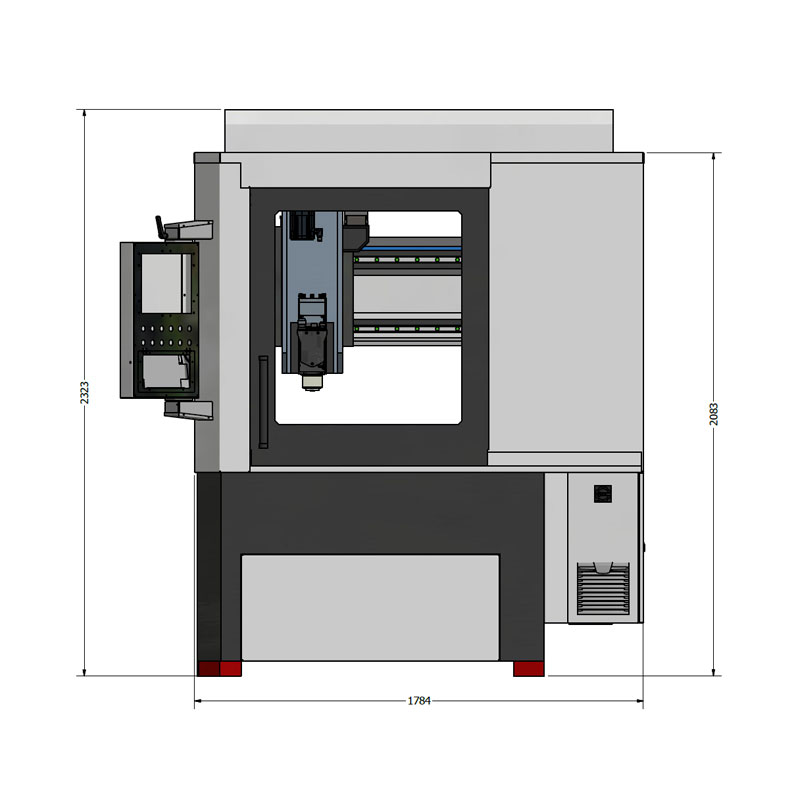

1070 mm x 1010 mm x 2090 mm |

1700 mm x 1300 mm x 2170 mm |

1800 mm x 1600 mm x 2170 mm |

1070 mm x 1010 mm x 2170 mm |

1610 mm x 1410 mm x 2170 mm |

| Table load | 700 kg | 1600 kg | 3500 kg | 900 kg | 2500 kg |

| Compressed air connection | 6-7 bar | 6-7 bar | 6-7 bar | 6-7 bar | 6-7 bar |

| Connected load | 3×400 V / 16 A | 3×400 V / 16 A | 3×400 V / 32 A | 3×400 V / 16 A | 3×400 V / 32 A |

| Power | 6 kVA | 10 kVA | 15 kVA | 10 kVA | 15 kVA |

* Optional drive version