HSC 350 MG

Our smallest and “lightweight” machine. With only 700kg still easy to handle but solid and strong enough for outstanding surface quality. The mineral die cast basement and portal structure are rigid and vibration damping.

The 40-station HSK-E25 tool changer belongs to standard equipment as well as a water cooled 40.000rpm spindle with up to 6kW power.

The HSC 350 is also extremely space efficient! With only 1060mm x 960mm x 2100mm (LxWxH, without operators panel) it fits through almost every door.

Standard equipment:

- T slot table with additional fitting holes 16H7 in 50/100mm grid

- Hand wheel for controlling up to 6 axis with override for feed rate and spindle rpm

- automatic tool length measurement and break detection

- joblist and zero point offset managemt

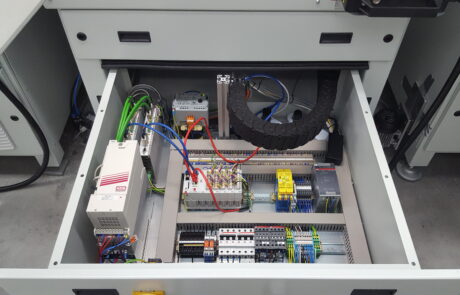

- network ready machine control for easy access and integration

- semi automatic central lubrication system

Technical data

| Feature | HSC 350 MG |

|---|---|

| Axis count | 3 |

| Travel (XYZ) |

380 mm x 350 mm x 180 mm |

| Axis of rotation | optional |

| Swivel axis | optional |

| Mounting surface (XY) | 368 mm x 360 mm |

| max. table load | 150 kg |

| Diffuser height Z | 210 mm |

| max. speed | 7 (10)* m/min |

| Spindle and tools | |

| Speed range rpm | 5.000 – 40.000 |

| Spindle power (water cooled) | 4kW (S1-100%), 6kW (S6-40%) |

| Tool clamping | HSK-E25 |

| Tool changer | 40-fach |

| max. length from lower edge of spindle cone | 110 mm |

| max. tool length (depending on collet length) approx. | 70 mm |

| Dimensions (XYZ) | 1070 mm x 1010 mm x 2090 mm |

| Table load | 700 kg |

| Compressed air connection | 6-7 bar |

| Connected load | 3×400 V / 16 A |

| Power | 6 kVA |

* Optional drive version